Best Extra Virgin Olive Oil: How It Is Tested

Morocco Gold Extra Virgin Olive Oil Analysis Explained

Updated 22nd January 2025

Summary

- The results of our annual harvest analysis confirms the exceptionally high quality of Morocco Gold Extra Virgin Olive Oil (EVOO), now available to our valued customers.

- Our extra virgin olive oil is vigorously tested to ensure the most accurate information is displayed on our label.

- Multiple factors contribute to the taste and health benefits of the best quality extra virgin olive oil.

Contents

- Why Is Cold Pressing Our Olives So Important?

- What Happens After Harvesting & Pressing Extra Virgin Olive Oil?

- Extra Virgin Olive Oil: The Testing Process

- From Olive Fruit To Bottled Extra Virgin Olive Oil

- Extra Virgin Olive Oil Quality Attributes

- Morocco Gold Extra Virgin Olive Oil : Latest Harvest Analysis

Why Is Cold Pressing Our Olives So Important?

Cold pressing is synonymous with high-quality extra virgin olive oil. This method involves crushing the olives at room temperature to extract their oil without the use of heat or chemicals. The result is a purer, more natural product.

The absence of heat is key. Heat can degrade the oil’s natural antioxidants and nutrients, which are vital for both flavor and health benefits. By keeping the process cold, producers preserve these essential compounds, resulting in a more nutritious oil.

Additionally, cold pressing maintains the oil’s vibrant color and rich aroma. These sensory qualities are often lost when heat is applied, robbing the oil of its character. A cold-pressed olive oil retains its natural essence, offering a taste that’s as close to the fresh olive as possible. Cold Pressing is a common way to make extra virgin olive oil that removes the need for heat or chemicals. Morocco Gold is made exclusively from olives which are cold pressed within 24 hours of picking ensuring an incredibly rare, extra virgin olive oil of exceptional quality, extraordinary health benefits and a taste like none other.

What Happens After Harvesting & Pressing Extra Virgin Olive Oil?

We have been asked, if your extra virgin olive oil is pressed in November each year, how come it takes until around march before it is available? – a fair question.

There areThere are two key things that happen during this time. After pressing, our olive oil is stored in specialised, temperature controlled stainless steel, nitrogen purged (to remove all the air) tanks. This allows a period of time for the oil to rest or ‘settle’. As a purely natural product, it will contain some residues from the pressing and centrifuge processes that whilst not harmful, it is best not to have in our bottles of Morocco Gold. We prefer not to filter our extra virgin olive oil as this can remove some of the natural nutrients within the oil.

During this settling period, we have our olive oil tested. Our extra virgin olive oil is tested in Morocco by the Moroccan Food authority, ONSSA (Office National de Sécurité Sanitaire des produits Alimentaires). It is further independently tested in the UK by Campden BRI who are the country’s leading food testing agency, so there is a double guarantee of extra virgin olive oil quality.

Our current harvest results:

Acidity level:

Peroxide:

Wax Content:

UV ABS. K232:

K268:

Polyphenols:

0.2%

2.6 MEQ O2/KG

60.2 MG/KG

1.967

0.146 MG/KG

626 MG/KG

Extra Virgin Olive Oil: The Testing Process

More people have immersed themselves in the world of what makes for the best extra virgin olive oil. We are delighted to share the testing process data.

Therefore, extra virgin olive oil has to be extracted exclusively from olives. Solely by mechanical means, without excessive heating or any chemical processing. As required by International trade standards. For instance, extra virgin olive oil is a natural product that does not need much to be preserved. It contains antioxidants, Nature’s preservatives that extend the oil’s shelf life if stored in a sealed bottle, away from the light and in cool temperature.

Compared to wine making, extra virgin olive oil production is a simpler and faster process. But unlike wine, olive oil does not improve with age. It is at its best when fresh but will unavoidably change over time. Yet the volatile components that give extra virgin olive oil like Morocco Gold its desirable “green notes”. For example, the flavour and aroma that consumer and tasters desire, will eventually disappear over time.

We determine the oil grade using three basic laboratory assays. They measure olive oil’s attributes related to quality of the olive fruit and its processing and assess the oil’s present state.

From olive fruit to bottled extra virgin olive oil

Superior extra virgin olive oil like Morocco Gold is obtained only when harvest, milling and processing of olives are properly managed. Along those steps, there are two naturally occurring and interrelated processes that must be understood as they impact the olive oil’s quality. These steps are lipolysis and oxidation. Lipolysis (a form of hydrolysis) begins on the olive fruit as it ripens. It is caused by enzymes present in the fruit. It is removed with the vegetation water. Lipolytic enzymes break down major olive oil components and generate free fatty acids, precursors to olive oil change of condition.

Oxidation (more specifically, auto-oxidation) happens when oil is in contact with oxygen and air. Firstly during the milling process. Secondly storage in tanks and bottles. Oxidation produces peroxides from some fatty acids. Peroxides are unstable compounds which yield volatile and non-volatile components. For instance these give rise to off-flavours and undesirable aromas in the oil (secondary oxidation). Oxidation, photo oxidation, is usually minor and negligible if the oil is stored in the dark. In conclusion, lipolysis generates free fatty acids and oxidation causes the formation of peroxides from these fatty acids (primary oxidation). Eventually leading to rancidity and degradation of the oil over time (secondary oxidation).

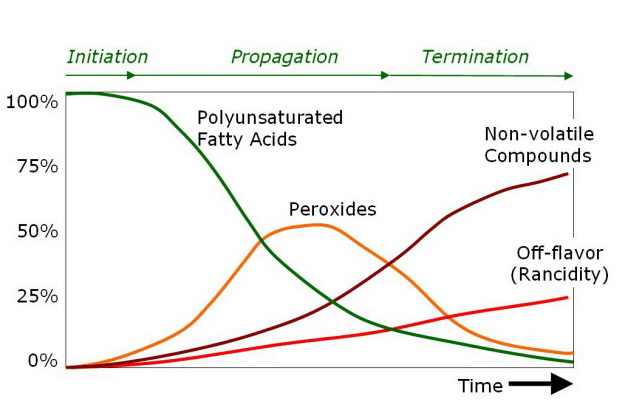

Attaining extra virgin olive oil of superior quality requires minimizing the generation of free fatty acids by hydrolysis and delaying the onset of oxidation. The oxidation process in extra virgin olive oil takes place in three stages: initiation, propagation and termination.

Figure 1: Olive Oil Oxidation

Figure 1 shows how the oxidation of fatty acids in olive oil changes with time. Once the oil has been decanted or centrifuged, the free fatty acid level (or free acidity) will gradually decline while the oil remains in storage. [Declining free acidity is represented in the graph by the down-sloping line from upper-left to lower-right.] During the initiation stage, free fatty acids present in the oil become slowly oxidized, giving rise to small amounts of peroxides. Since peroxides, in turn, decompose into other substances, the overall peroxide level does not increase rapidly. However, when certain levels of peroxides are reached in the oil, a propagation stage ensues during which peroxide levels will rapidly increase, as peroxides beget other peroxides. [Increasing accumulation of peroxides is represented in the graph by the rising left-side of the curve.] During the termination stage, peroxides further decompose giving off numerous off-flavour compounds that humans can detect, even if present at extremely low concentrations—below parts per million. Therefore, even when just a tiny fraction of peroxides degrade into undesirable compounds, the oil will begin to taste rancid. [Rancidity is represented by the lower line rising from the bottom-left to the right of the graph.]

If the quality of the olive fruit was very good and free acidity levels were low when processing the olives, there may be a time lag of up to 3 years before peroxide levels in the oil become problematic (that is, the initiation period is long). But if the olive fruit was spoiled, the temperature during processing was too high or the malaxation time too long, there is an increased risk of reaching higher peroxide levels much sooner, thereby shortening the oil’s shelf life. [Peroxides’ evolution is represented by the bell-shaped curve in the centre of the graph.]

Extra Virgin Olive Oil Quality Attributes

The basic olive oil parameters measured analytically are: Free Fatty Acids (FFA), Peroxide Value (PV) and UV absorbance. In combination, they will indicate proper or inadequate handling of the olive fruit prior to milling. This will assess the oil’s present state of oxidation.

Free Fatty Acids (FFA) or Free Acidity

As mentioned earlier, free fatty acid formation precedes most, if not all oil deterioration. Free acidity levels increase by hydrolysis of the major oil molecules in the fruit (triglycerides) early in the production process, from harvest through milling, while water and plant enzymes are still in contact with the oil. For this reason, milling the olives soon after harvest, and promptly separating oil from vegetation water are critical to maintaining a low initial free acidity level, essential for higher-quality oil.

Free acidity values provide an indication of how the fruit was handled prior to processing and the length of time from harvest to milling. Free acidity is also an early indicator of the potential longevity of the oil. Higher quality oils recently produced, will exhibit very low acidity. It may be no higher than 0.35% in the best extra virgin olive oils (EVOO) like Morocco Gold.

Peroxide Value (PV)

Peroxides are generated by oxidation of polyunsaturated fatty acids in the oil (linoleic and linolenic acids). They are flavourless. Peroxides are unstable, usually building up slowly and eventually leading to oil rancidity. The onset of this decay process may be delayed for up to 3 years in good extra virgin olive oil, rich in radical-scavenging antioxidants. But once peroxides are present, rancidity is unavoidable. Peroxide Value identifies the early stages of oxidation. Subsequent oxidation is detected through UV absorbance and by the oil’s sensory properties, which result from the peroxides’ breakdown.

To reduce peroxide levels and therefore delay oxidation of high peroxide oils, blending may be a viable recourse. Otherwise, refining is the only option to eliminate peroxides and remove off-flavor substances. Obviously, the resulting product will not be extra virgin olive oil.

Ultraviolet (UV) Absorbance

UV tests determine the ultraviolet light absorbance measured by shining UV light through the oil at several specific wavelengths. Absorbance at K232 nm (nanometers), K270 nm and Delta K correlate with the state of oxidation by detecting specific oxidized compounds, some generated from secondary oxidation, and also detect possible adulteration with refined oils.

Interpreting Analysis Results

The standard set of quality tests for grading olive oil includes organoleptic (sensory) tests and the three basic analyses: FFA, PV and UV. The International Olive Committee’s (IOC) olive oil standards specify precise measurement thresholds. The grades are extra virgin, virgin. Whenever analytical parameters (FFA, PV, and UV) exceed a given threshold, the oil is classified as the next lower quality grade. But experts agree that a quality EVOO can meet more stringent thresholds than the standard. Reflecting the freshness and quality of truly superior oil. The standard FFA threshold is 0.8% acidity, but fresh, high-quality EVOO can certainly achieve FFA values of 0.3 % or lower.

Peroxide Values vary widely over time. Some oils may meet the EVOO’s 20 meq/kg threshold while already showing early signs of rancidity. Experience indicates that high-quality, recently milled oils exhibit peroxide values below 12 meq/kg. Truly excellent oils may have PV as low as 7 meq/kg (9 meq/kg for organic oil). An oil with a low PV will have a longer shelf life.

Regarding UV absorbance, though the standards call for K232 below 2.5 and K270 below 0.22, superior olive oil will exhibit K232 values below 1.85 (2 for organic oil) and K270 below 0.17. As mentioned before, low values correlate with high-quality oil, as UV absorbance detects early and later states of oxidation.

A basic set of analysis provides producers and buyers. Ultimately customers with valuable information about the quality of fruit and processing that went into the extra virgin olive oil. That is why we have included the results of our own analysis on each and every bottle of Morocco Gold extra virgin olive oil.

Morocco Gold Extra Virgin Olive Oil: Latest Harvest Analysis

We are delighted to share the headline results of our latest harvest analysis for Morocco Gold Extra Virgin Olive Oil (EVOO), now available to our valued customers.

Acidity level:

Peroxide:

Wax Content:

UV ABS. K232:

K268:

Polyphenols:

0.32%

8.5 MEQ O2/KG

60.2 MG/KG

1.967

0.146 MG/KG

278mg/kg

These are the headline analysis results we include on the rear label of each and every bottle of our extra virgin olive oil. (See https://morocco-gold.com/about/how-to-read-the-olive-oil-label/)

These remarkable findings confirms the unwavering quality of this rare and delightful extra virgin olive oil sourced from Morocco. Not only does it boast an exquisite taste, but it also offers health-enhancing qualities due to its high polyphenol content.

Extra Virgin Olive Oil (EVOO): The Chemistry of Excellence

By examining the chemical characteristics of extra virgin olive oil, we gain insights into the meticulous care taken during its production and storage. It reveals details about the cultivation, transportation, harvesting, pressing, and packaging processes. Rigorous chemical analysis also ensures that the oil is free from any adulteration. Extra virgin olive oil is held to the highest chemical standards, making it a guarantee of unparalleled quality.

Defining Extra Virgin Olive Oil (EVOO): Certification with a Purpose

To earn the prestigious extra virgin olive oil accolade, Morocco Gold oil surpasses strict criteria in production methods, taste profile, and chemical composition. Here’s what it means to be certified extra virgin olive oil:

Single Source Purity: Our extra virgin olive oil is derived solely from one source, without blending it with other oils, even if they are of extra virgin quality.

First-Pressed Freshness: We extract our oil from young olives, pressed within 24 hours of harvesting for unparalleled freshness.

Mechanical Extraction Only: Our olives are cold-pressed mechanically at temperatures consistently below 27°C, with no chemical processing.

Low Acidity Levels: With an acidity level (oleic acid) below 0.8%, our oil greatly surpasses the threshold for quality.

Flawless Taste and Aroma: Our extra virgin olive oil is defect-free, possessing a perfect taste and irresistible aroma.

Extra Virgin Olive Oil (EVOO) : The Lower The Acidity, The Longer The Shelf-Life:

The lower the acidity, the higher the quality the extra virgin olive oil and the longer the shelf-life. We take immense pride in offering you the best of the best olive oil.

The Power of Polyphenols – Unlocking The Health Benefits Of Extra Virgin Olive Oil (EVOO)

Our exceptional extra virgin olive oil is not just about culinary excellence; it also contains an abundant level of polyphenols renowned for their health benefits. Polyphenols are potent antioxidants, neutralizing harmful free radicals that can do serious harm within your body.

Morocco Gold extra virgin olive oil: the ultimate ‘superfood’ that delivers numerous health benefits. Tested locally in Morocco by ONSSA (the National Office for the Sanitary Protection of Food Products) and the to International Olive Council standards. This exceptional extra virgin olive oil stands out with its polyphenol content well in excess of 250mg/kg, which is the level approved by the European Food Safety Authority for health claims.

When it comes to everyday health and well-being, here are just some of the ways Morocco Gold extra virgin olive oil can make a difference:

- Reduces the risk of cardiovascular diseases

- Provides a beneficial effect on ulcers and gastritis

- Keeps the digestive tract healthy

- Helps regulate blood pressure and healthy cholesterol levels

- Assists in managing diabetes and lessens the severity of osteoporosis.

Indulge in Morocco Gold extra virgin olive oil, a superior choice that embraces both exceptional taste and remarkable health benefits.